Today’s industrial world

is shifting towards more sustainable solutions that offer power efficiency.

Electrostatic Precipitators (ESPs) are vital for cleaning flue gases in power

plants, steel, and cement industries. But it is crucial to make them power efficient;

that’s where Transformer-Rectifier

(T/R) sets come in.

In this article, we will discuss the role of transformer rectifiers in keeping

ESPs reliable, efficient, and effective.

Let’s dive in!

1. Ensuring precise

voltage control

Transformer-Rectifiers take AC voltage

and convert it into the high-voltage DC power required to get dust particles

moving in ESPs. And precise voltage is everything here. Get it too low, and

dust collection is a waste of time. Get it too high, and you are burning energy.

The good news is modern Transformer-Rectifier sets are pretty good at keeping

the voltage stable even when the flue gas conditions are all over the place,

which is a significant bonus for ESP efficiency.

2. Maximizing energy efficiency

Industrial power is

expensive, and energy efficiency is a top priority. T/R sets are designed to

optimize power usage by adjusting current and voltage according to dust load

and gas flow.

This dynamic operation reduces unnecessary energy consumption, lowers operating

costs, and ensures your plant meets sustainability targets without compromising

on emission control.

3. Extending ESP Lifespan

Frequent electrical

stress can wear out ESP components faster. By providing controlled, steady DC

power, T/R sets reduce stress on collecting plates and electrodes. The result?

Less maintenance, fewer replacements, and a longer lifespan for your ESP equipment.

Think of it as giving your ESPs a gentle but effective “energy massage” that

keeps them healthy.

4. Enhancing Operational Flexibility

Industrial processes

rarely run at a constant pace. Load variations, seasonal changes, or process

adjustments can affect flue gas properties. A well-designed T/R set adapts in

real-time to these changes, ensuring consistent dust collection efficiency. This

flexibility not only improves emissions control but also supports regulatory

compliance without constant manual intervention.

5. Facilitating Advanced Monitoring and Diagnostics

Today’s T/R sets often

come with innovative monitoring capabilities. Operators can track voltage,

current, and other performance metrics remotely. Some systems even offer

predictive alerts for maintenance, helping avoid downtime. By integrating

intelligence into power supply, T/R sets make ESP operations more innovative,

safer, and more reliable.

Conclusion

A Transformer-Rectifier

set is more than just a power supply; it is the component that ensures your

electrostatic precipitator runs efficiently. They keep things running with a

focus on energy efficiency and equipment lifespan. They help keep your industrial

processes consistent and emissions under control.

At Ador Powertron,

we understand the stuff when it comes to building top-notch T/R solutions that

meet industrial needs. We give plant owners the confidence to get on with the

job, maximizing efficiency, keeping downtime to a minimum & meeting the

environmental standards with ease.

Ready to enhance your ESP efficiency and cut power costs? Partner with

Ador Powertron to explore advanced Transformer-Rectifier solutions

designed for reliability, energy savings, and superior performance.

Get in touch today to

see how our expertise can power your industrial operations efficiently and

sustainably.

About the Author: ADOR

POWERTRON Ltd., an ISO 9001-certified company, is one of the largest

manufacturers and suppliers of Transformer-Rectifier (T/R) sets and controls in

the world.

With over 20,000

High-Voltage transformer rectifier units supplied & 200+ satisfied

customers to its credit over the past 35 years, it has established a strong

footprint within the Power, Cement, Steel, Pulp, and Paper industries across 82

countries spanning six continents.

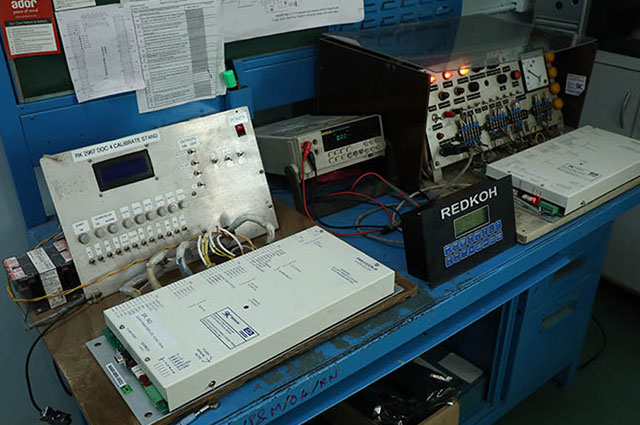

ADOR T/Rs use in-house

software. Additionally, OEM software can be integrated to manage and control

the ESP.

ADOR is committed to

investing in these areas and will research innovative solutions to fight

pollution and use sustainable energy. To achieve this, ADOR has collaborated

with Redkoh, the world’s leading precipitator control company.

#EnergyEfficiency

#PowerElectronics #Sustainability #SwitchModePowerSupply #HydrogenInnovation