What do you notice about the tall chimneys in power plants, steel mills, or cement factories? There is something more important inside, innovative technology working hard to keep the air cleaner. One of the most vital tools in that operation is the electrostatic precipitator (ESP), and the ESP power supply is the heart of it.

Manufacturers are focused on not just productivity, but also running smarter, fulfilling strict emission regulations, and lowering downtime. And that’s where smart ESP power supplies come in. Along with powering equipment, they enable predictive maintenance and assure compliance with ever-tightening environmental criteria.

Let’s dive in!

1. Why ESP Power Supplies Matter for Cleaner Operations

An electrostatic precipitator reduces emissions before they leave the chimney by charging dust particles and then capturing them on a collecting panel. But the efficiency of an ESP depends on its power supply.

Traditional setups offer the voltage and current needed to run the ESP, but smart power supplies continuously optimize energy delivery, keeping the ESP running at peak performance. Despite process variations within the plant, it continues to offer cleaner air and smoother compliance with emission norms.

2. Predictive Maintenance

Downtimes are expensive; that’s why waiting until something breaks cannot be an option in industries that run 24/7. That’s where smart ESP power supplies shine. It monitors parameters such as sparking, temperature fluctuations, or current leakage, as these predict issues before they escalate. Instead of breakdowns, operators receive timely alerts, which help maintenance teams step in proactively—this results in higher uptime, fewer surprises, and lower costs.

3. Smart Power for Sustainable Operations

Another advantage of ESP power supplies is energy efficiency. Traditional units over-consume power, but these modern systems smartly regulate energy use. They adjust output based on real-time dust loads and process conditions, ensuring that only the required amount of energy is used.

This helps with emission compliance, supports broader sustainability goals, and cuts unnecessary energy consumption.

4. Emission Regulations Compliance

With stricter environmental regulations becoming increasingly stringent every year, industries such as cement, steel, and power generation must adhere to these regulations. Failing to meet emission standards can pose a reputational risk and result in heavy fines and operational hurdles.

Intelligent ESP power supplies act as a safeguard here. Their precise control and intelligent monitoring ensure ESP systems consistently deliver their best. This helps industries stay compliant without frequent manual adjustments.

5. Integration with Industry 4.0

The future-ready part is that smart ESP power supplies can integrate with plant automation and control systems. This means operators don’t just get raw data, but also actionable insights from their dashboards.

This makes it easier to align maintenance, compliance, and production schedules. In this way, ESPs control pollution and simultaneously contribute to more innovative and cleaner manufacturing.

In Essence

Lastly, electrostatic precipitators remain one of the most trusted technologies for emission control. But when integrated with a reliable, intelligent power supply, they can reach their full potential. Smart ESP power supplies take things to the next level by enabling predictive maintenance. This allows energy efficiency and ensures compliance with stricter emission regulations.

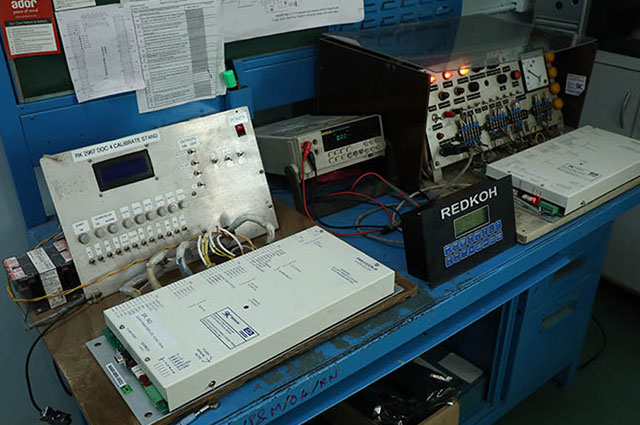

At Ador Powertron, we offer advanced ESP power supplies crafted for the challenges of advanced industry. If you are looking to cut downtime or move toward more sustainable operations, our solutions are engineered to fuel your growth.

To explore our ESP power solutions and achieve predictive maintenance, contact us now.