Running an industry and still relying on reactive maintenance? This reactive approach leads to unexpected failures, downtime, and reduced performance. Unlike traditional industrial maintenance, predictive AI tools can help identify issues before they incur significant costs and extend the equipment's lifespan.

Here's how industries can successfully get an innovative and proactive system when AI is combined with a robust Emission Control System.

Let's start!

1. Start with a deep assessment of your existing air system

Let's begin by understanding the current condition of your industrial air system. Firstly, evaluate the equipment, including ducts, fans, ESPs, and supporting infrastructure, within your Emission Control System. This helps identify repeating errors, gaps, and components that require attention. A clear performance baseline can help AI models in understanding the system's normal behavior and precisely detect deviations that may interrupt operations. This allows the AI tools to deliver meaningful insights.

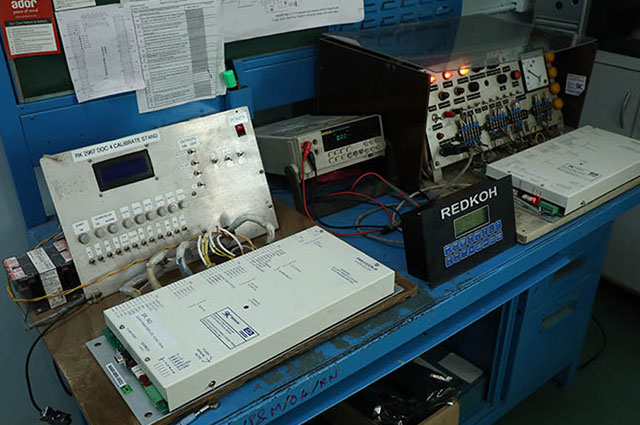

2. Build a strong data foundation with IoT sensors

Predictive AI = Real-time data = Sensors

By aligning the sensors together, we can get a steady flow of information that the AI can use to understand the system's health. This offers information about patterns, early warnings, and fluctuations that affect the efficiency of the Emission Control System.

When your machinery is entirely digitized, AI can monitor performance round the clock and act as an early detection mechanism for future failures.

3. Use AI models to predict failures before they occur

Data infrastructure done? Now, tools can analyze operational behavior. Patterns like filter clogging, sudden airflow changes, declining ESP efficiency, or abnormal energy consumption are all studied.

With this information, AI can easily identify the component that has the highest likelihood of failure. The maintenance team can fix the issue before it turns into an emergency shutdown. When integrated into your Emission Control System, AI can also optimize performance by identifying subtle inefficiencies that human operators may overlook.

4. Automate alerts and maintenance responses

A smart predictive maintenance setup acts on problems and helps you by setting up automated alerts, ensuring critical warnings reach the right person. Reduces human errors; supervisors receive real-time notifications directly when needed. These computerized responses allow the maintenance team to plan repairs, prevent operational interruptions, and adjust settings accordingly.

In a modern Emission Control System, automation closes the gap between detection and action, significantly improving reliability and safety.

5. AI insights for long-term system optimization

Over time, predictive AI becomes more intelligent as it learns from the behavior of equipment and functional trends. It can highlight recurring issues, identify energy-saving opportunities, and suggest operational adjustments that improve system efficiency and effectiveness.

For example, AI may recommend tuning ESP power levels, upgrading outdated components, or modifying airflow paths to improve particulate capture. These insights help organizations not only maintain system health but also enhance the overall performance of their Emission Control System. By transforming raw data into strategic recommendations, AI facilitates long-term planning, cost reduction, and improved emission compliance.

Conclusion

The way air systems are managed is transforming and evolving more proactively, thanks to predictive AI tools. When combined with a well-designed Emission Control System, it offers reduced downtime, improved performance, and safety to the workforce. Data-driven insights are the future of maintenance, and enterprises that adopt AI early can gain a substantial functional advantage.

Ready to Bring Predictive AI into Your Air System?

Ador helps you modernize your maintenance strategy with a smart step: integrating predictive AI tools into your industrial air systems. Are you looking to improve performance, decrease downtime, and save maintenance expenses? Now is the perfect time!

Contact us now to build your intelligent maintenance strategy.