Industries such as cement, power, steel, and chemicals are under constant pressure to meet increasingly stringent emission norms. The solution to this: Electrostatic Precipitators (ESPs). But simply maintaining ESPs is no longer enough. To achieve meaningful emission reduction, plants must modernise the way their ESPs are powered and supported with the right ESP mechanical and spares.

In this blog, we will discuss how upgrading to modern power supply technology can significantly enhance collection efficiency, reduce emissions, and extend the life of your ESP system.

Let’s begin.

1. Why traditional ESP power supplies limit emission reduction

Older ESP power supplies operate at low frequencies and often lack the responsiveness required to handle fluctuating dust loads and gas conditions. This results in unstable voltage levels, frequent sparking, and inconsistent particle charging. Even if the ESP structure is sound, inefficient power delivery limits overall performance.

When ESPs operate below optimal electrical conditions, emissions increase despite regular maintenance of the ESP’s mechanical and spares. Modern power supply technology addresses this gap by delivering stable, precise, and adaptive power, enabling ESPs to operate closer to their ideal performance range.

2. How modern power supplies improve particle collection efficiency

Modern high-frequency and digitally controlled power supplies provide smoother DC output and faster response to process changes. This enables better corona formation and more effective charging of fine particles, which are often the hardest to capture.

With improved electrical performance, ESP internals, such as discharge electrodes, collecting plates, and rapping systems, operate more efficiently. When combined with well-maintained ESP mechanical and spares, modern power supplies significantly improve dust collection efficiency, resulting in visibly lower stack emissions.

3. Reduced sparking means lower wear and better reliability

Sparking is a major cause of performance loss and mechanical stress in ESP systems. Frequent sparks not only reduce collection efficiency but also accelerate wear on internal components. Modern power supplies use intelligent control algorithms to detect and suppress sparks instantly, allowing the ESP to operate at higher average voltages without damaging internal parts.

This controlled operation reduces stress on critical ESP mechanical and spares, such as insulators, electrodes, and rapper mechanisms. The result is improved system reliability, fewer shutdowns, and more consistent emission control over time.

4. Energy efficiency and lower operating costs

Upgrading ESP power supply technology is not just about emissions; it’s also about efficiency. Modern power supplies consume less energy due to reduced losses and optimised switching behaviour. For plants running large ESP installations, this can translate into substantial energy savings.

Lower power consumption also means reduced heat generation, which further protects the ESP mechanical and spares from thermal stress. Over time, this reduces maintenance frequency and helps plants achieve both environmental and cost-efficiency goals.

5. Smarter monitoring and predictive maintenance capabilities

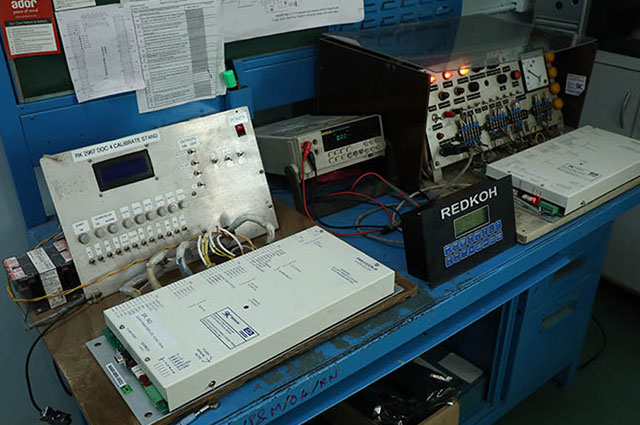

Modern ESP power supplies seamlessly integrate with modern technologies and enable real-time tracking of voltage, current, spark rate, and system health. Operators gain valuable insights that help identify issues before they escalate into failures.

When paired with quality ESP mechanical and spares, this data-driven approach allows for predictive maintenance rather than reactive repairs. Plants can schedule servicing more effectively, avoid unplanned downtime, and maintain stable emission levels even under varying operating conditions.

Wrapping up

Routine ESP maintenance is not enough to effectively reduce emissions; it requires smarter power delivery. This is why many are shifting to modern power supply technology, which allows ESPs to operate at peak efficiency, improve particle collection, and reduce energy consumption.

With decades of experience in ESP power systems and emission-control technologies, Ador Powertron has played a key role in helping industries modernise their ESP installations. Their advanced power supplies, control systems, and engineering expertise enable plants to achieve cleaner air, improved compliance, and long-term operational reliability.

Ready to Upgrade Your ESP and Cut Emissions?

If your plant is looking to reduce emissions, improve ESP performance, and extend the life of your ESP mechanical and spares, now is the time. Contact us today.